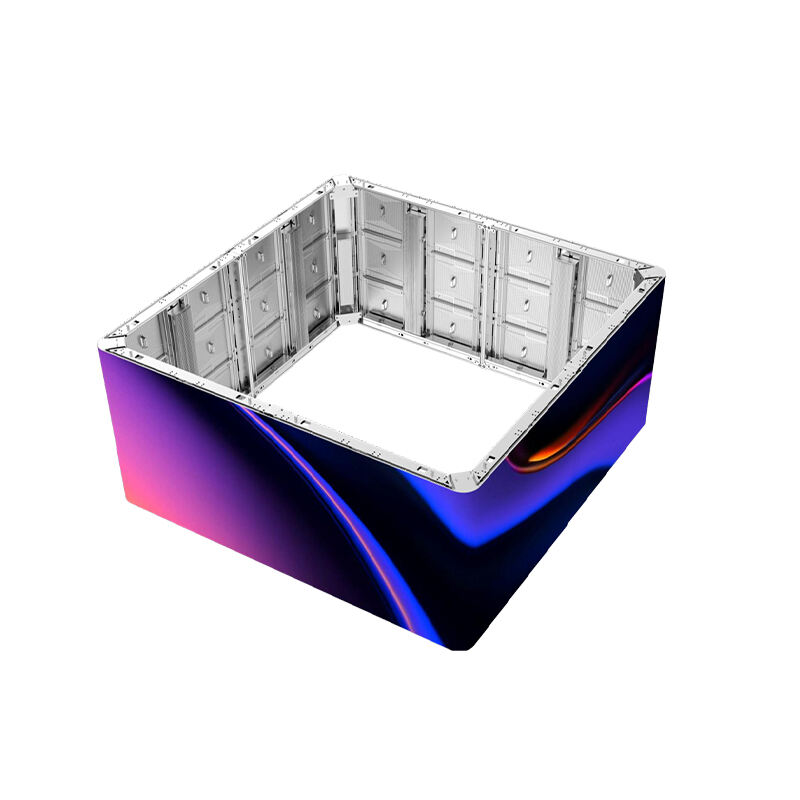

Outdoor LED Displays: Weatherproof and Eye-Catching

Weatherproof Technology in Outdoor LED Displays

Exterior LED screens, meanwhile, must be given top-notch weatherproofing so that they are still functioning smoothly in water, dust, or heat beyond the norm. Strong materials, thermal control systems, and only the highest protection standards are all brought toghether to allow for 24 by 7 running time. This technology, also crucial for use cases such as highway billboards, stadiums and transportation infrastructure, failure of which could lead to costly downtimes or threat to life and property.

IP Ratings Explained for Waterproof LED Screens

The Ingress Protection (IP) code defines a display’s resistance to solids and liquids. For outdoor environments, IP65 and IP67 are the most common benchmarks:

| IP Rating | Protection Level | Use Cases |

|---|---|---|

| IP65 | Dust-tight; withstands water jets | Covered stadiums, walkways |

| IP67 | Dust-tight; survives 1m submersion | Flood-prone areas, ports |

Displays rated below IP54 lack sufficient protection against wind-driven rain or humidity, increasing failure risks by up to 34% in coastal regions. Always verify third-party IP certification—self-reported ratings often overstate performance.

Thermal Management in Extreme Temperatures

Outdoor LED panels must operate in temperatures ranging from -20°C to 50°C. High-end systems use aluminum heat sinks to dissipate internal heat, paired with forced-air cooling for desert climates. In contrast, subarctic installations integrate heating elements to prevent snow accumulation on screens.

Material Innovations for Weather Resistance

Recent advancements focus on corrosion-resistant aluminum alloys and hydrophobic coatings that repel water 40% faster than traditional materials. UV-stable polycarbonate layers now block 99% of harmful rays, reducing color fading by 60% over 5 years. For coastal deployments, manufacturers use marine-grade stainless steel fasteners.

High Brightness and Visibility Features

Outdoor LED displays require adequate luminosity to ensure visibility during direct sunlight or cloudy days. Key specifications focus on nits brightness and anti-glare treatments.

Nits Measurement and Sunlight Readability

Nits (candelas per square meter) quantify visible light intensity. Higher nits values counter sunlight washout—displays require ≥5,000 nits for daytime clarity in urban settings. Panels may exceed 10,000 nits for coastal or desert installations.

Anti-Glare Surface Treatments in Outdoor Displays

Micro-roughness etching diffuses reflected light, eliminating "hotspot" glare. Treatments include:

- Matte coatings: Scatter light photons

-

Chemical film overlays: UV-cured resins with haze values of 30-45%

These adjustments preserve brightness while supporting 160° viewing angles critical for high-traffic zones.

Vandal-Resistant and Structural Features

Vandal-Resistant Aluminum Alloy Frames

Outdoor LED displays require robust structural protection against impacts and unauthorized tampering. Vandal-resistant frames are engineered from reinforced aluminum alloys—combining lightweight properties with exceptional strength. These alloys undergo specific hardening processes to achieve impact ratings that withstand pressures exceeding 40,000 PSI.

Wind Load Testing and Seismic Adaptations

Wind load validation involves computational fluid dynamics simulations followed by physical testing in wind tunnels—certifying stability against Category 3 hurricane gusts (130+ mph).

Corrosion-Resistant Coatings for Coastal Areas

Advanced anti-corrosion treatments deploy multi-stage defense: industrial-grade anodization creates a dense oxide barrier, while hydrophobic nanocoatings enable water droplet sliding angles below 10°.

Outdoor Digital Signage Applications

3D LED Screens in Retail Advertising

Retailers leverage 3D LED displays to create immersive brand experiences, increasing dwell time by 40% in commercial districts.

Stadiums and Public Event Displays

Modern sports arenas integrate high-resolution LED walls with live broadcast feeds to display real-time replays and player stats. Public event organizers utilize modular LED configurations to adapt screens for concerts and civic announcements.

Buying Guide for Outdoor LED Displays

Key Specifications: Waterproof Level vs Brightness

Balance IP ratings against brightness (measured in nits). Displays with IP65/IP66 certification withstand heavy rain and dust, while screens delivering 5,000–8,000 nits ensure visibility under direct sunlight.

Evaluating True 24/7 Operation Capability

Authentic 24/7 operation requires:

- Thermal management systems maintaining efficiency at -30°C to 50°C

- Redundant power supplies with ≥0.1% failure rate

- Energy-efficient drivers reducing power consumption

Future Trends: Curved and Modular Outdoor Displays

Curved LED screens provide wider viewing angles, while modular designs enable custom shapes with <2mm bezels. Emerging “plug-and-play” modules simplify repairs without shutting down entire screens.

FAQ

What does an IP rating signify in LED displays?

An IP rating determines the level of protection the display has against solids and liquids. Common outdoor ratings are IP65 (dust-tight and withstands water jets) and IP67 (dust-tight and can survive 1m submersion).

Why is thermal management important for outdoor LED displays?

Thermal management is crucial to ensure that LED displays operate efficiently across extreme temperatures. It prevents overheating in warm climates and ensures functionality in cold temperatures.

How do advancements in materials impact outdoor LED display performance?

Material innovations like corrosion-resistant alloys and hydrophobic coatings enhance durability by preventing water damage and corrosion, while UV-stable materials protect against sun damage, extending the lifespan of displays.

What are nits and why do they matter for LED displays?

Nits measure the brightness of an LED display. High nits values are essential for visibility in bright daylight, particularly in sunny or urban environments.

Hot News

Hot News