Why choose front maintenance for LED screens?

What Is Front Maintenance in LED Screens?

Definition and Core Concept of Front Maintenance LED Displays

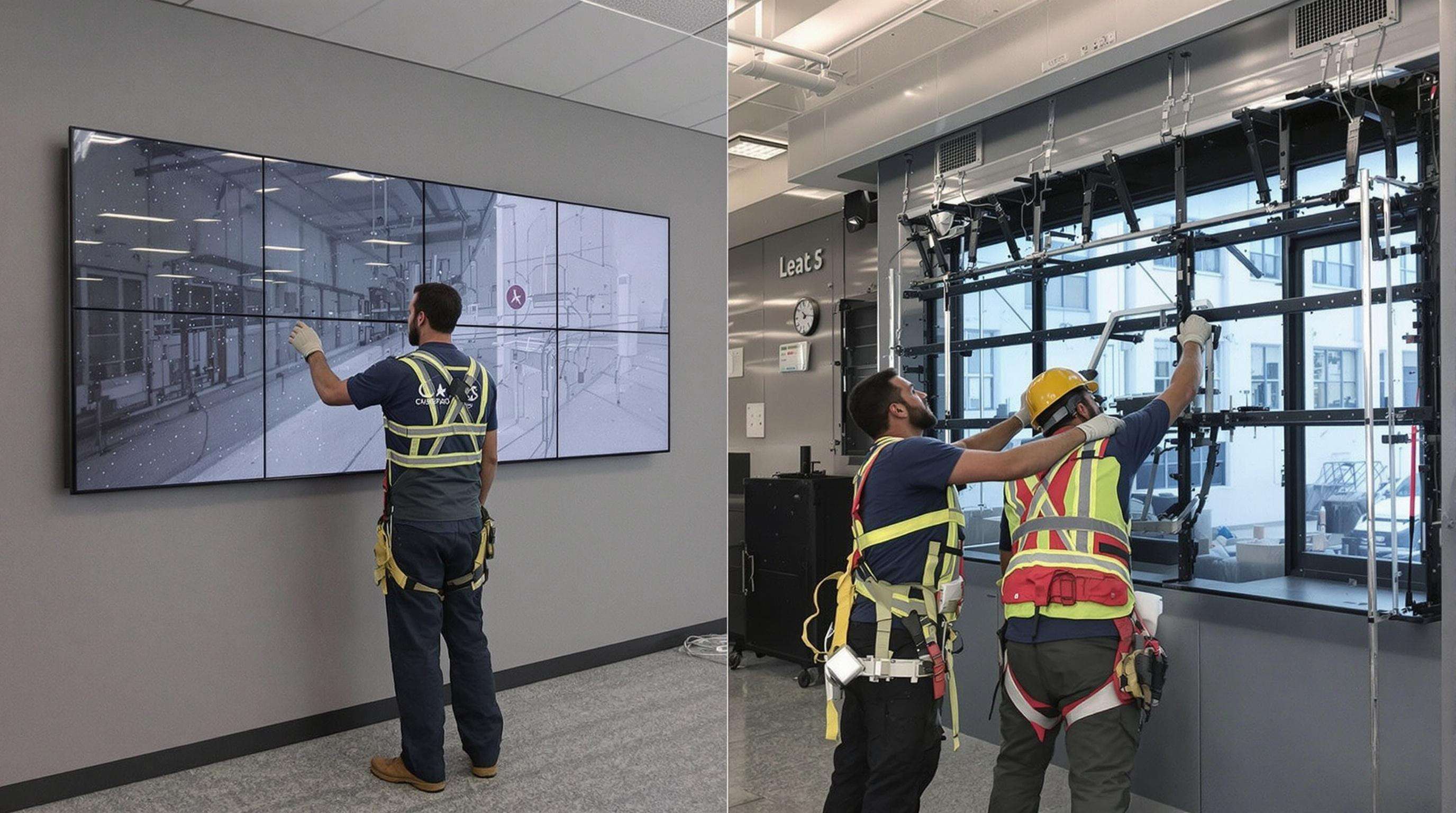

LED screens with front maintenance are built so techs can service them right from the viewer side. No more crawling behind equipment to fix problems, something that's standard practice with older LED setups. Most modern installations use these handy features like magnets holding panels together or those snap-in latches that let workers swap out modules quickly without ever touching the backside. The folks at Display Innovation did some testing last year and found that fixing issues takes about half the time (around 52%) faster with front access systems versus going around back. Makes sense why these have become popular in tight spaces or areas where safety regulations make it hard to get behind the screen for repairs.

Structural Design Features Enabling Front-Accessible Maintenance

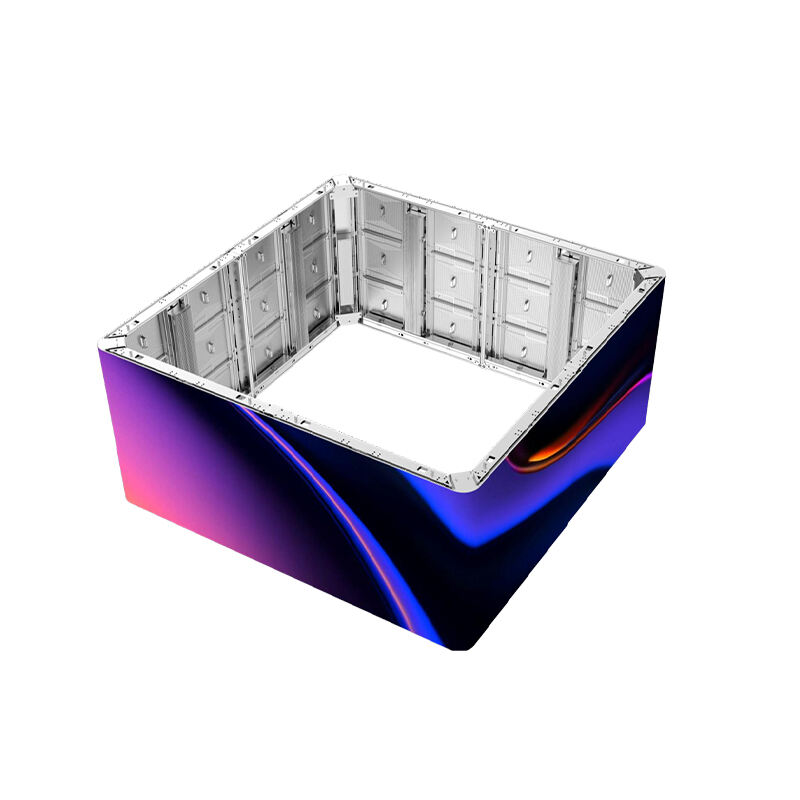

These displays feature modular frameworks with precision interlocking components, allowing individual panels or power supplies to be replaced without disturbing adjacent units. Key design elements include:

- Ultra-thin cabinets (40mm depth) that support flush wall mounting

- Front-facing ports for managing signal and power cables

- Self-aligning connectors that ensure accurate pixel alignment during reinstallation

This architecture removes the need for rear clearance, a major benefit in environments like retail stores and airport terminals where space optimization is critical.

How Front Maintenance Differs From Traditional Rear Maintenance Approaches

Most traditional rear access systems need around 18 to 24 inches of space behind the display just to service them properly. That kind of room isn't always available when installations are cramped or mounted high up somewhere. Front maintenance solves this problem completely by allowing installation without any clearance at all. Techs no longer have to risk their necks climbing behind those big screens hanging from ceilings or squeezing into awkward spots where there's barely enough room to move. Safety folks keep pointing out these situations as real hazards on job sites. Some tests done with digital signs actually found that replacing modules takes less than eight minutes each panel when using front service models, while trying to do the same work from the back side can take over twenty two minutes per panel instead.

Key Advantages of Front Maintenance LED Screens

Easy Front Access Enhances Serviceability and Reduces Complexity

Front maintenance allows direct replacement of modules from the viewing side using magnetic or tool-free mechanisms. This design simplifies repairs, especially in wall-mounted or sealed installations.

Improved Maintenance Efficiency and Reduced Operational Downtime

By enabling targeted repairs without dismantling mounting structures, front-serviceable LED screens drastically cut downtime. In retail environments, average service time drops from 8 hours to under 90 minutes per incident (Digital Signage Institute 2024). As a result, front-maintenance displays remain operational 98% of the year, outperforming rear-access models, which average 89% uptime.

Enhanced Safety in High-Altitude and Confined-Space Installations

When installing screens at busy places like airports, sports arenas, or train stations, having front access means workers don't have to climb up on scaffolding or use those big boom lifts just to get behind the display. This cuts down on falls and keeps everyone compliant with safety regulations. According to something OSHA released last year about LEDs, working from the back side of these installations actually causes quite a few accidents during setup. The same principle applies underground too. Maintenance crews working in tunnels or inside control rooms benefit greatly when they can service equipment from the front instead of crawling into tight, dangerous spaces where visibility is poor. Just making sure technicians aren't stuck in awkward positions makes the whole worksite safer for everybody involved.

Space-Saving Design Ideal for Tight or Indoor Environments

LED screens that can be accessed from the front cut down on how deep they need to be installed by somewhere between 65 to maybe even 80 percent compared with regular setups since there's no need for space behind them. These kinds of displays work really well in tight spots like corporate reception areas, small shops that aren't wider than about fifteen feet, and older buildings where changing the structure isn't allowed. The thin design means they fit within fire exit regulations too, which applies to around ninety two out of every hundred American cities according to what I've read. That's pretty impressive when considering building codes these days.

Sleek, Aesthetically Pleasing Appearance Supports Modern Architectural Integration

Front maintenance tech lets designers create really clean looks without those annoying screws, seams, or air vents showing on the front. These days we see lots of models with black matte panels and super thin edges around 0.5mm thick that just disappear against dark walls. Some come with optional magnetic faceplates too, which helps everything look continuous rather than patchy. That makes them work great in places where appearance matters most like concert spaces, upscale shops, and other spots where design is king.

Front vs. Rear Maintenance: A Practical Comparison

Functional and Operational Differences Between Front and Rear Maintenance Systems

Front maintenance allows direct access to modules from the display face using simple tools, removing the need for rear clearance. In contrast, rear maintenance requires dedicated behind-screen access, which is often impractical. Industry studies show front-access systems reduce average repair times by 66% compared to rear-access models.

| Factor | Front Maintenance | Rear Maintenance |

|---|---|---|

| Access Requirements | Front-facing only; no rear space needed | Requires dedicated rear access corridor |

| Repair Complexity | Single technician, tool-based module swaps | Multi-person teams often required |

| Design Flexibility | Suitable for wall-mounted & enclosed spaces | Limited to areas with rear access routes |

Challenges of Rear Maintenance in Elevated or Space-Constrained Setups

Rear maintenance is particularly problematic for high-mounted or flush installations. In double-sided outdoor signs or ceiling-mounted displays, lack of rear access forces full disassembly for repairs. This increases labor costs by up to 40% due to safety equipment, rigging, and extended downtime.

Accessibility, Cost, and Long-Term Value: Direct Comparison of Both Approaches

Although front maintenance systems carry a 15–20% higher initial cost, they deliver superior long-term value through faster repairs, reduced labor, and improved safety. By minimizing downtime and preserving floor space, they achieve 34% greater ROI over five years compared to rear-access models, making them a strategic investment for continuous-operation environments.

Ideal Applications for Front Maintenance LED Screens

Front maintenance LED screens are best suited for environments where rear access is impractical. Their modular, front-serviceable design excels in three primary use cases:

Indoor Installations Where Rear Access Is Impractical

In museums, conference centers, and retail stores, these displays eliminate the need for rear service corridors. While traditional LED walls require 24–36 inches of backspace, front-access models reduce structural depth by 40–60% while maintaining effective thermal management—essential for indoor climate control and energy efficiency.

Commercial and Public Spaces Benefiting From Minimal Space Requirements

Transportation hubs and corporate lobbies use front maintenance screens to maximize usable floor area. A 2023 digital signage survey found that 78% of space-constrained venues reported greater installation flexibility with front-access designs. Their slim profile supports integration into columns, curved walls, and architecturally complex surfaces without compromising serviceability.

Case Study: Front Maintenance Deployment in Airport Display Systems

Airports increasingly adopt front-access LED screens for flight information displays. At a major European terminal, technicians achieved 92% faster module replacements by servicing 10-meter-high displays directly from the front, eliminating scaffolding requirements. This approach reduced display-related downtime by 63% during peak travel periods, significantly improving passenger communication reliability.

Long-Term Operational Benefits and Cost Considerations

Reduced downtime through faster diagnostics and module replacement

Front maintenance enables resolution of 89% of common issues from the viewing side (DisplayTech Insights 2023), avoiding full disassembly. This cuts average repair times by 40–60%, a crucial advantage in 24/7 environments like broadcast studios and control rooms.

Lower labor and maintenance costs over the screen’s lifecycle

The simplified service process reduces labor and equipment demands through:

- 55% fewer personnel needed per maintenance event

- 80% reduction in specialized equipment requirements

- Elimination of structural disassembly costs

These efficiencies contribute to 22% lower total ownership costs over five years, with savings increasing as display size and complexity grow.

Addressing the myth: Are front maintenance LED screens more expensive upfront?

While initial pricing is 8–12% higher than traditional models, the investment typically pays for itself within 18 months. When factoring in extended warranties, energy efficiency, and reduced downtime, 72% of users report a positive ROI within three years (Digital Display Quarterly 2023), confirming the long-term economic advantage of front maintenance technology.

Hot News

Hot News